Description

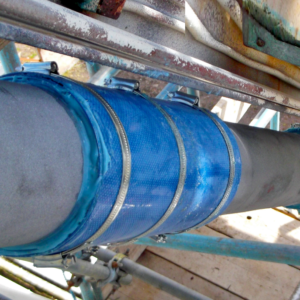

ViperSkin™ – bi-axial, hybrid carbon and glass fiber, pre-saturated system to blend the unsurpassed strength and stillness of carbon with the ease and use of a moisture-cured, factory-saturated polyurethane. Pre-saturated by producer.

The system ensures appropriate fiber-to-resin content ratios to deliver reliable performance in restoring pipeline integrity on lines with complex geometry

Features

- Moisture-cured polyurethane resin

- Factory-saturated fiber

- Full engineering consultation and support

- Non-shielding

- Can be applied to any geometry including, but not limited to elbows, tees, and flanges

- Design conforms to ASME PCC-2, ASME B31, ISO 24817, DOT, API, and CSA Z662 standards for nonmetallic reinforcing solutions

Benefits:

- Factory saturation of moisture-cured polyurethane resin reduces composite field preparation time by more than 50%

- Factory saturation ensures the right fiber-to resin ratio with constant strength and mechanical properties

- Easy application in any conditions, including damp or sweating pipes and in submerged environments

- No heating or post-curing

- Suitable for irregular shapes and geometries

- Can be used on lines of any diameter

ViperSkin® is a register trademark of CSC Operating Company, LLC.