Description

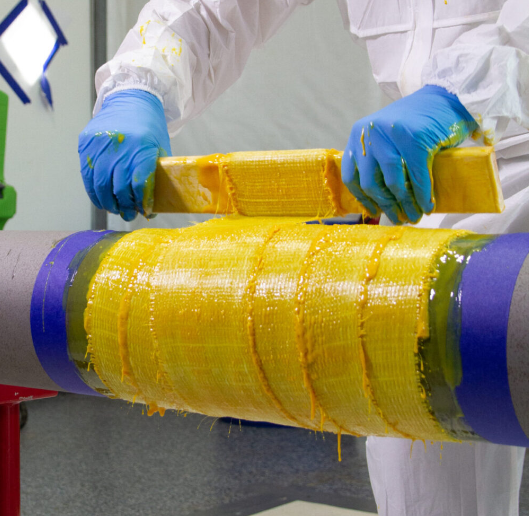

ThermoWrap® is an engineered, field-saturated repair system made of proprietary fiberglass cloth applied with a two-part epoxy and a high-modulus filler material. ThermoWrap® is used globally in plants, refineries, tank farms, terminals and on offshore assets as a pressure-containing repair to seal leaks and as a reinforcing repair to restore the strength of a pipe in the axial and circumferential directions. It is ideal for repairs involving complicated geometry, including tees, flanges, and varying diameter pipe.

ThermoWrap® is available in multiple kit sizes for any temperature and diameter pipe and can be installed with minimal disruption to operations. It repairs through-wall defects and installs easily

in challenging environments where there is complicated pipe architecture.

ThermoWrap® includes:

- ThermoWrap – operates up to 200oF (93oC)

- ThermoWrap MT – operates up to 313oF (156oC)

- ThermoWrap HT – operates up to 430oF (221oC)

- ThermoWrap 500 (pre-impregnated) – operates up to 500oF (260oC)

Thermo Wrap® is a register trademark of CSC Operating Company, LLC.